ENERGY MANAGEMENT

Participating in International Initiatives for Energy Efficiency and Carbon Reduction

As of April 29, 2022, Primax joined the RE100 initiative, pledging to implement the use of renewable energy at all its locations and actively setting renewable energy targets. In addition to promoting energy-saving solutions, the company has been gradually increasing its purchase of renewable energy certificates since 2019, with the aim of reaching carbon neutrality by 2040.

GHG Emission Control Through Partnership with Third-party Organizations

Since 2010, we have been working with SGS, a third-party institution, to identify and measure GHG emitted by our plants, which helped enforce our GHG control strategies. By disclosing energy indicators, we intend to show the world how far wehave accomplished in mitigating environmental impacts, and our ability to respond to carbon controls, rising operating costs, and changes in energy supply and prices.

The Statistical Scope Includes

- Direct GHG Emissions

- Energy Indirect GHG Emissions

- Other Indirect GHG Emissions

- GHG Emission Intensity

Although Primax Group does not operate any production facility in Taiwan and is not subject to GHG emissions reporting and control, we still take the initiative to survey GHG emissions and pay close attention to regulatory requirements. The carbon trade system is being implemented in the Mainland, while provincial governments are starting to introduce control over emissions. In the meantime, we adopt rigorous control and strive to reduce GHG emission to avoid being impacted by new policies and laws.

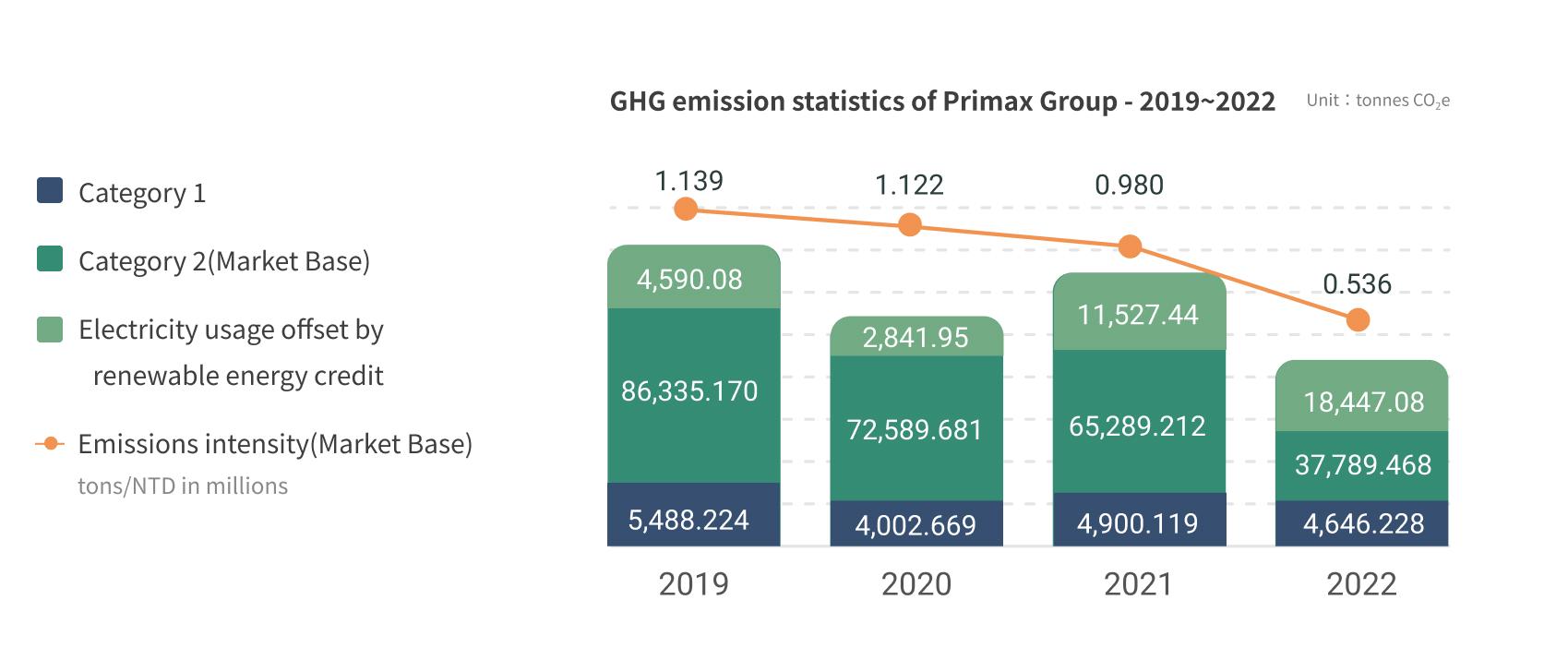

GHG Emission Statistics of Primax Group

- The Group’s Scopes 1 and 2 greenhouse gas emissions in 2022 were be 42,435.696 tons of CO2 e/year (Market Base),

Compared with 2021, a decrease of

22,753.635

tons of CO2 e / year,

Or about

39.54

%

Compared with 2019, a decrease of

49,387.699

tons of CO2 e / year,

Or about

53.79

%

- The greenhouse gas emission intensity in 2022 was 0.536 tCO2 e / million NTD,

Compared with 2021, a decrease of

45.33

%

Compared with 2019, a decrease of

52.96

%

International Renewable Energy Certificate (I-REC)

- The main reasons are due to the active implementation of energy-saving initiatives at various plants. The Dongguan Primax, Chongqing, Kunshan, Huizhou Tymphany, Thailand Primax, and Thailand Tymphany plants purchased Renewable Energy Certificates (I-REC). Additionally, the Dongguan Dongju, Chongqing, and Huizhou Tymphany plants directly utilize electricity generated from solar power.

- In 2022,

Renewable Energy Offset

32,610,000

kWh

Renewable Energy Offset

18,447.08

tons of CO2 e

Accounting for

32.04

% of the electricity used

- Since 2019, the cumulative purchase of Renewable Energy Certificates has led to

A reduction of

37,406.548

tons of CO2 e

Effective Management Strategies

Energy consumption is a main cause of climate change, because the combustion of non-renewable fuel creates greenhouse gas among other environmental impacts. Making efficient use of energy is key to mitigating climate changes, and is a goal we strive to achieve by continually improving our production procedures.

Strategy

Energy Management

Investing in energy-saving measures based on the net-zero pathway and goals, establishing an internal energy-saving culture, and continuously reducing operational energy consumption.

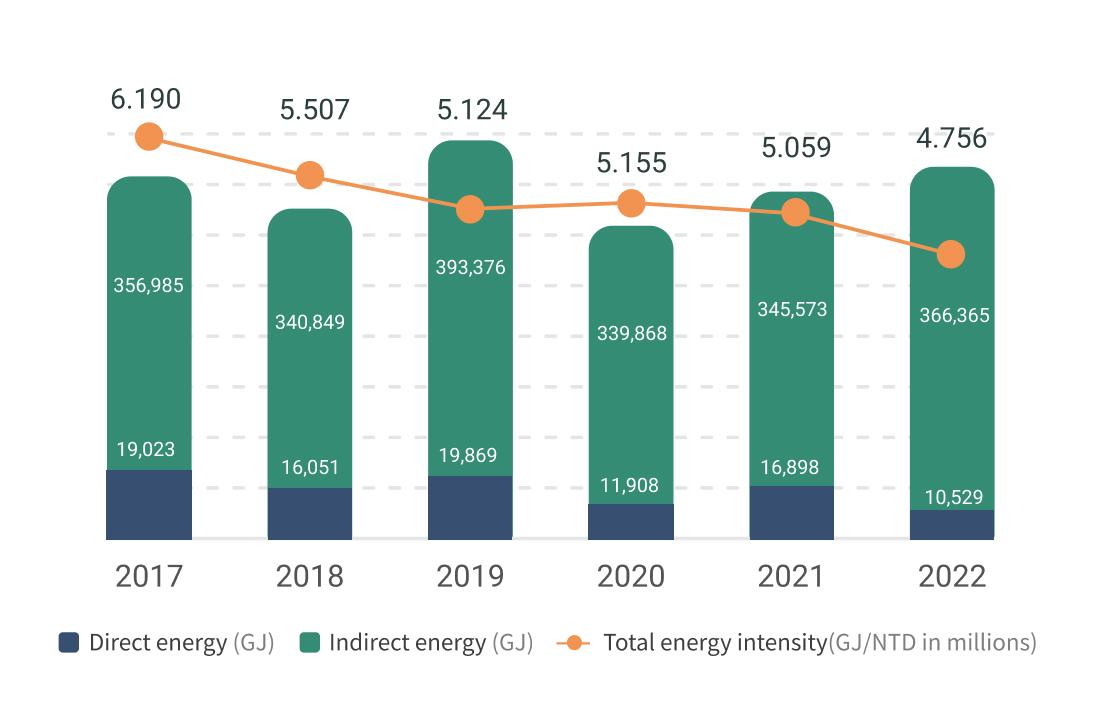

Energy Consumption

- Each year, Primax gathers more sophisticated data to enhance its existing energy strategies.

- In 2022, the energy intensity compared to the previous year:

There was a

5.98

% reduction

Use of Renewable Energy

- Since 2019 , Primax has been actively promoting a renewable energy utilization plan. This initiative mainly involves purchasing Energy Attribute Certificates, developing in-house solar power generation facilities, and engaging in Power Purchase Agreements for renewable energy procurement to increase the utilization of renewable energy.

- Renewable energy certificates: In 2022, we purchased a total of 32,610,000 kWh, with a cumulative purchase of 55,765,000 kWh of electricity.

- Renewable energy agreement: In 2022, we entered into a Power Purchase Agreement for renewable energy, purchasing 205,306 kWh of electricity.

- Generate solar power for use: Primax has been generating our own solar power through in-house solar power facilities, with a total generation of 362,697.23 kWh.

- The total usage amounted to 33,178,003.23 kWh.

The total electricity consumption

32.60

%

The total energy usage

31.69

%

Energy-Saving Action Plans

- In order to make production sites more energy-efficient, we have been exploring all solutions possible to reduce energy consumption. One of the methods we have taken towards achieving this goal is to continually replace old and power-hungry equipment.

- To promote renewable energy usage and enhance energy efficiency, our concrete measures include selfbuilding solar power facilities, replacing natural gas boilers with air-source heat pump water heaters, implementing behavior changes in the use of air conditioning and lighting facilities, replacing energy-efficient motors, optimizing the utilization of air compressors, upgrading and improving the energy efficiency of chiller systems, replacing lighting in factories, warehouses, and street lights with LED lights or solar-powered lights, and replacing air compressors with variable frequency drives.

Energy-Saving Measures Statistics

- Energy-Saving Measures Statistics for Primax Group in 2022

Power saving benefits

2,353,759

kWh

Energy saving benefits

8,474

GJ

Carbon reduction benefits

1,208.64

T CO2e

Emphasizing Water Resource Conservation Strategies to Achieve Water-saving Goals.

Water Management

- In today's context of water scarcity and increasing demand, the utilization and management of water are critical issues that businesses need to prioritize in their operations. Therefore, we continuously monitor the water usage in our production facilities and are committed to reducing water consumption.

- To strengthen Primax Group’s water resource management strategy, all nine major operating sites have obtained the ISO 14046 Water Footprint Verification Statement and formulated a water balance map of each plant to help reinforce our water conservation strategy.

Strategy

- The company complies with international initiatives to manage water-related risks and implement appropriate response activities. It aims to achieve water conservation goals and minimize potential harm to the environment.

The Water Pressure of Primax Group

Taiwan

Low - Medium (1- 2 )

Dongguan, Huizhou, Dongcheng

Medium - High ( 2 -3)

Kunshan, Thailand

High ( 3 - 4 )

Total volume of water recycled in 2022 was measured at 35.88 million liters, representing 4.12 % of group-wide water usage. The recycling helps minimize use of fresh water, discharge of wastewater, and the overall environmental impact.

Managing Wastewater, Air Pollution, and Waste to Implement Pollution Prevention Measures.

Wastewater Management

- River not only serves as a source of water, but also provides habitat that is vital to creating biodiversity. For this reason, we have devoted part of our environmental focus to keeping rivers clean. By tracking the volume of water discharged, we are able toensure effective management of production effluents. Since 2016, the company has been continuously implementing various environmentally friendly measures. Furthermore, our stringent requirements on hazardous substances in raw materials and consumables exceed international regulations. The discharge of wastewater does not contain harmful substances that would adversely affect receiving bodies of water. With the exception of the Liuwu and Thailand plants that discharge industrial wastewater, all other plants within the Primax Group utilize water solely for domestic and public purposes. The water is discharged into local sewage systems in accordance with regulations, posing no significant impact on local water bodies.

Regarding Wastewater Management, We are Committed to Implementing Various Environmentally Friendly Measures to Ensure Sustainable Practices.

01

New construction of a painting water circulation pond for wastewater treatment improvement.

02

Implementing automatic sludge retrieval for recycling, reducing wastewater discharge.

03

Revamping the existing in-house industrial wastewater treatment plant by installing pH monitoring devices and emergency collection tanks for automatic monitoring of values.

04

Enhancing emergency management practices.

Air Pollution Management

Air pollution poses adverse impacts on climate, ecosystem, air quality, habitat, agriculture,and human and animal health. On going threats such as deterioration of air quality, ocean acidification, deforestation and public health issues have awoken law makers local and abroad to regulate gas emissions. For this reason, we regularly measure emission data that is relevant to causing air pollution, and strive to reduce emission of such gases.

We have summarized 3 main points from the air pollution data:

01

No ozone depleting substances (ODS) were emitted from the Company's productions. The air conditioning equipment at the server room of the Taipei Headquarters used small amounts of R22, a refrigerant restricted under the Montreal Protocol, and it was replaced with eco-friendly refrigerant.

02

The Company is primarily involved in assembly works, which is less prone to air pollution. No NOx or SOx is released from production activities.

03

Other air pollutants are entirely compliant with local regulations. According to local regulations applicable to Primax plants, production processes that involve coating and surface technology (SMT) are subject to environmental tests once a year. For the coating process, substances of the most concern include benzene, toluene, xylene, and volatile organic compounds (VOC); for the injection molding process, substances of the most concern are non-methane hydrocarbons; and for the SMT process, substance of the most concern is tin.

Prevention and Control of Air Pollution

- The main types of pollutant generated from plants include: volatile organic compounds (VOC), benzene, toluene, xylene, Total VOCs, non-methan hydrocarbons (NMHC), lead and lead compounds, and tin and tin compounds.

The Process of Air Pollution Treatment

To treat the above air pollutants, Primax first collects organic and particulate pollutants separately from exhaust in an enclosed environment, then uses the appropriate air pollution control equipment to treat the respective pollutions until they conform with emission standards.

The Improvement of Air Pollution Treatment

Our exhaust treatment process has been improved by adding UV photo degradation to existing water-sprinkling and activated carbon absorption. These three processes have effectively enhanced Primax's exhaust treatment capabilities at various plants.

2022 Primax Group Air Pollutant Emission Statistics

Waste Management

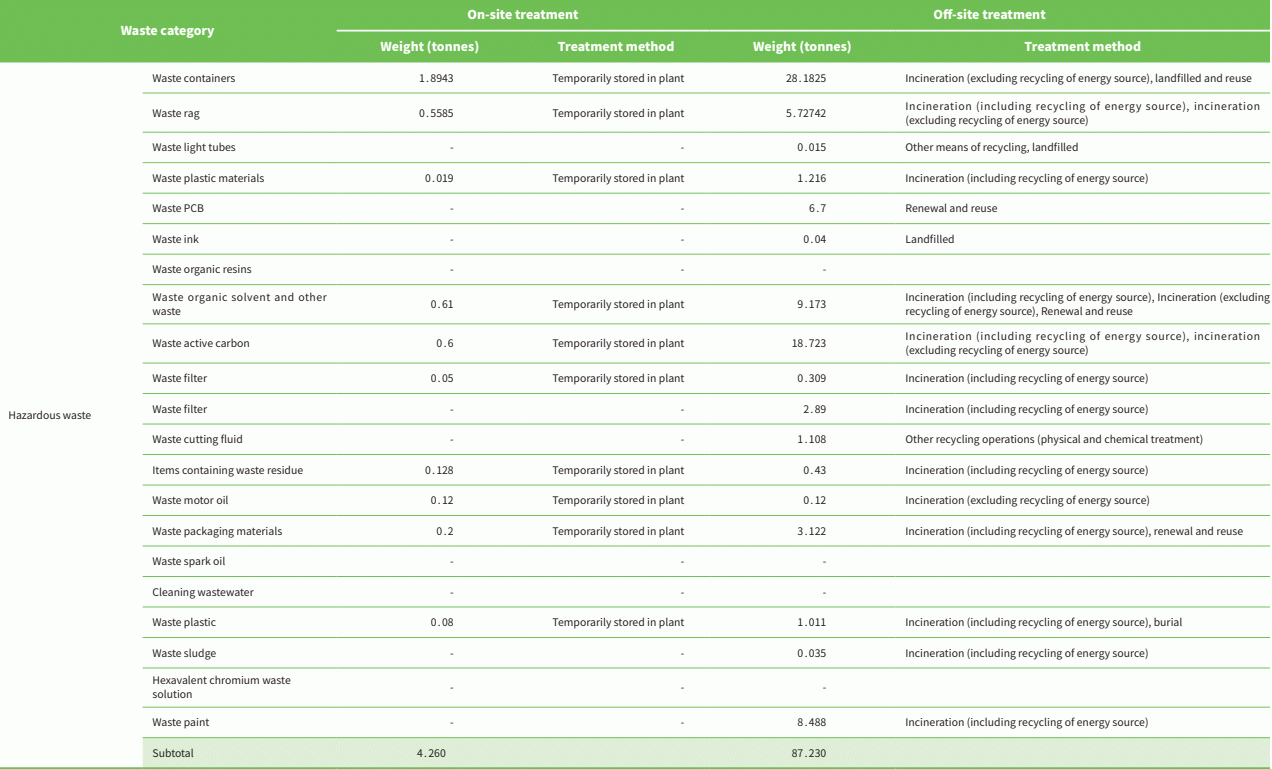

Aiming to reduce environmental impact, promoting internal and supply chain collaboration to minimize waste generation at the source and create opportunities for resource circulation. Waste produced by Primax Group can be classified into general waste (domestic waste),recycled waste, and industrial waste (including hazardous waste and general industrial waste).

The Statistics of Waste Consumption

- In 2022, the total amount of waste generated was 2,666.722 metric tons, which represents 34.41 % increase compared to the previous year. The main reason for this increase was the higher volume of waste generated at four locations: Primax Thailand, Tymphany Thailand, Tymphany Taipei, and Tymphany Shenzhen.

- In 2022, the waste was categorized based on disposal methods, with a total of 1,486.649 metric tons requiring disposal (1,392.766 metric tons of general waste and 93.883 metric tons of industrial waste). Additionally, 1,176.821 metric tons of waste were disposed of through transfer and recycling (900.437 metric tons of recyclable waste and 276.384 metric tons of general waste).

We try not to dispose or bury our obsolete equipment; instead, we do what we can to make them reusable one way or another, and have gone to great extent in making sure that these equipment are recycled in a proper manner that poses no threat to employees' health or the environment. All hazardous waste is properly stored and managed, and legitimate waste treatment companies are entrusted to handle the disposal through incineration.

In 2022, the waste management of the entire Primax Group was appropriate, and there were no major waste leakage incidents. All waste disposal methods were in compliance with local national regulations.

Environmental Protection Expenditure

- Primax Group has excelled in all assessment indicators and continues to be pro-active in improving production procedures and reducing energy consumption. Owing largely to our dedication in environmental protection, we have established our reputation as a role model business characterized by sound financial position, advanced technology, low resource consumption, low pollution, and high potentials. Environmental protection expenditure helps us determine the efficiency of our environmental measures, and provides useful information for cost analysis. We will be keeping track and analyzing these expenses in a continuous and thorough manner so that the executive management may have a better understanding to the value of investments madefor the purpose of mitigating environmental impacts.

We Will Continue to Develop a Comprehensive Environmental Accounting System to Track a Broader Variety of Information.

Waste Treatment

Emission Treatment

Remedial Costs

Prevention and Environmental Management Costs

Categorizing Environmental Expenses for 2022

Environmental Equipment and Engineering

Management System

Human Resources

Testing Equipment

Investments for Energy Saving

Information Management System