RESPONSIBLE SUPPLY CHAIN

Primax Electronic Ltd. Group are dedicating on enhancing business ethics and supplier chain environmentally friendly, & we follow international conventions, global initiatives, and legal regulations to assure Primax as well as whole supply chain is capable to seize the market opportunity.

Therefore, along with experiencing global pandemic, extreme climate, endanger human right violated war, we seek for a stronger, healthier supply chain solutions, & then we released a new Primax Supplier Code of Conduct on December 12, 2023. we will obligate to oversight the whole supply chain maturity.

Supplier Overview

Supplier overview

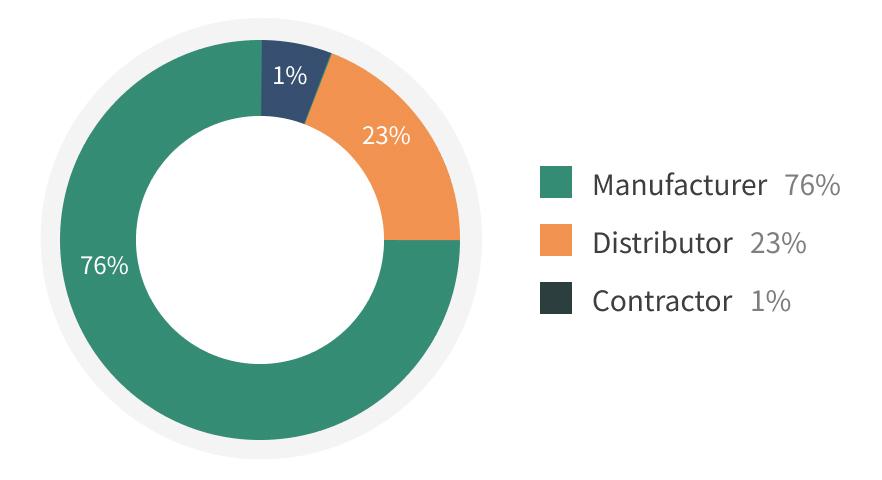

Proportion of Transaction Amount by Supplier

- There are three categories of supplier that are directly relevant to our production, including: 1, 505 raw material producers, 367 electronic parts distributors, and 6 subcontractors for a total of 1,878 .

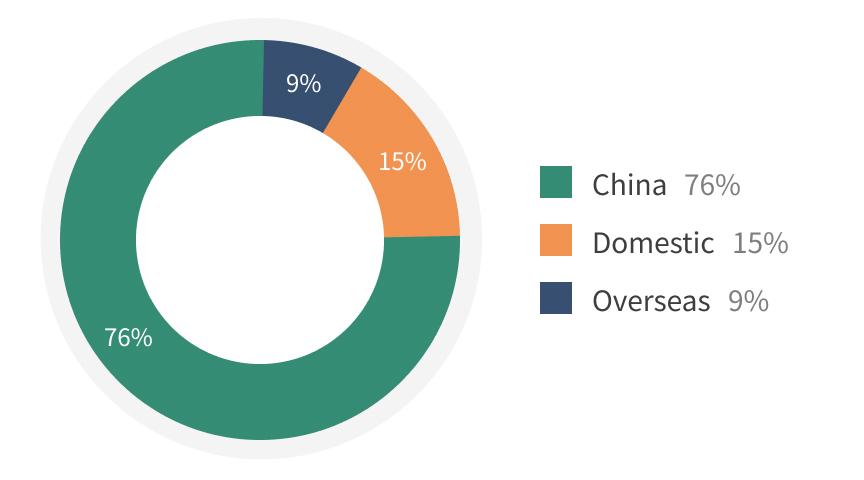

Proportion of Suppliers by Region

- Regionally, 281 suppliers were located in Taiwan, 1,422 were from China (including Hong Kong), and 175 were from other countries. Total transactions with suppliers amounted to approximately NT$58 billion in 2022.

Strategy

Sustainability Management of Suppliers

Establishing a sustainable and resilient supply chain is essential for reducing ESG system risks and addressing various operational challenges related to climate change, water management, and other critical aspects.

Supplier Audit

We take supplier reviews as a means to improve suppliers' capabilities. A comprehensive set of procedures has been developed to help suppliers improve and comply with the Company's supplier management policies.

Evaluation

All new Primax suppliers are required to pass QCDS+SER assessment before business.

Quality

Cost

Delivery

Service

Social Responsibility

The specific suppliers (e.g., world-renowned manufacturers, vendors specifically designated by customers etc.) are still subject to comply with QCDS+SER requirements, but they may adopt the supplier's declaration in document review (such as statement of environmental or other self-declared environmental statement). Then could be involved in the Approved Vendor List (AVL) after approval.

In 2022, initial questionnaires were conducted for 234 important suppliers to understand their management practices related to climate change and energy conservation activities.

Requirements for Suppliers

Primax's requirements for suppliers are not limited to performance and quality. Before collaboration, we require all new suppliers to sign the Integrity Statement and the Supplier Statement. They must cooperate in signing and submitting the environmental statement document reviewed by our company, including the responsible minerals statement, the restricted substances statement, company and the RBA Code of Conduct, to indicate that raw materials and finished goods they purchased have been in compliance with relevant initiatives, environmental laws and regulations, company policies and RBA Code of Conduct.

New Suppliers

- QCDS Evaluation (SER accounts for 5%)

- Supplier Statement

Existing Suppliers

- Online & offline communication and training

- Annual questionnaire surveys (social responsibility/conflict minerals/GHG, etc.)

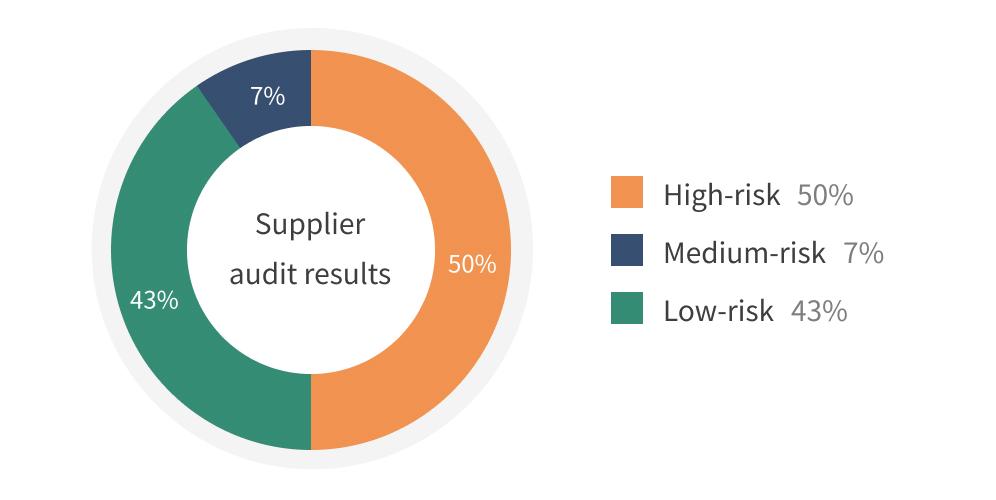

High-risk Suppliers

- Annual on-site audits

- CAP improvement tracking

- On-site follow-up reviews

Commitment

Not Using / Procuring Conflict Minerals

Not Using Restricted Substances

Adhere to and Comply with the RBA Code of Conduct

Suppliers

In 2022, our suppliers number underwent the review process

Total

216

new suppliers

Conflict Minerals Management and Due Diligence

Since 2012 , Primax has strictly complied with the "Conflict Mineral Law" and refrained from using and purchasing conflict minerals (such as: tantalum, tin, gold, and tungsten) that originate from Democratic Republic of the Congo, while at the same time demanded all suppliers to make a commitment to using responsible minerals and ensure that all minerals (such as: tantalum, tin, gold, and tungsten) used in production will not finance armed conflicts. This policy forms an essential part of our supplier management and product design, and we require suppliers to disclose information of their smelters and make announcements over GPPortal ® relating to any conflict metal discovered in their supply.

With the rapid growth of the electric vehicle industry, the scope of applications of rechargeable batteries is also expanding. Therefore, Primax Group has also required suppliers to disclose the use of cobalt ore since 2020 . Our current disclosures cover cobalt refineries (processing of cobalt concentrates and intermediate products) or recycling plants (processing of cobalt recycled materials).

Distribution of Smelters in Supply Chain

As per the disclosed information on smelters in the supply chain in 2022 suppliers announced

A total of

252

smelters

Supplier Management

Supplier due Diligence

We regularly conduct on-site evaluations of our suppliers and provide education and training on the assessment of hazardous substances and greenhouse gases.

Supplier Risk Assessment and Management

Online Inspection

Before Review

01

Risk Identification

During Review

02

Effective Improvement

After Review

03

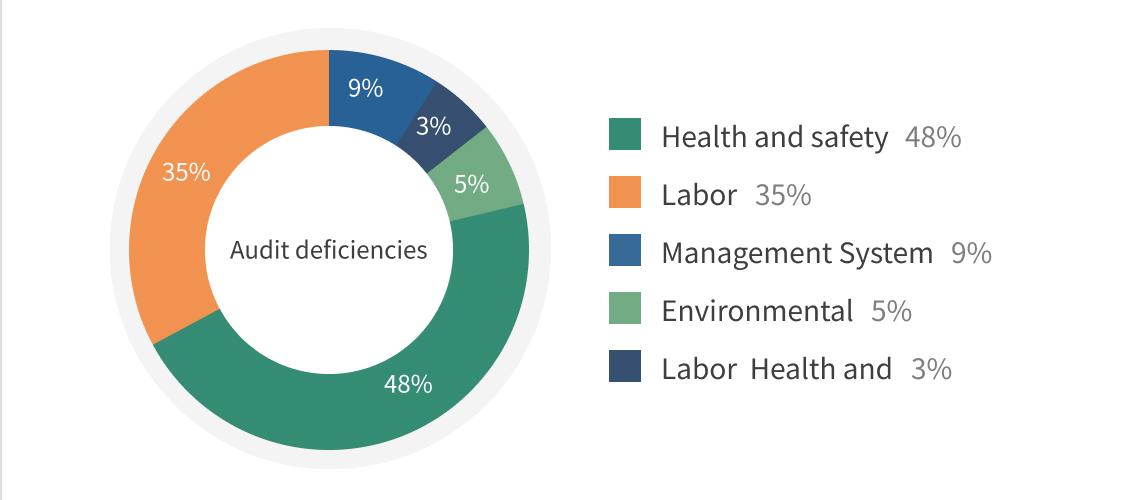

Supplier Audit Results

Suppliers Capacity Building Programs

Primax devotes to the participation of stakeholders and strive to create more opportunities and resources for suppliers to learn and improve. We have engaged a third-party institution since 2015 to organize annual social responsibility training for suppliers.

Cumulative Number of Suppliers Covered

To sum up, as of 2022 , Primax has covered social and environmental responsibility questionnaires, on-site audits, online training, and advocacy.

Total

1,754

suppliers

Working Hand in Hand with Suppliers for Sustainability

In 2023, we will respond to higher standards of supplier management principles, improve our supplier management mechanisms, and continue to demand that suppliers strengthen their focus on social and environmental responsibilities and enhance their management capabilities, collaborating with them to make continuous progress.

Suppliers for Sustainability Plan

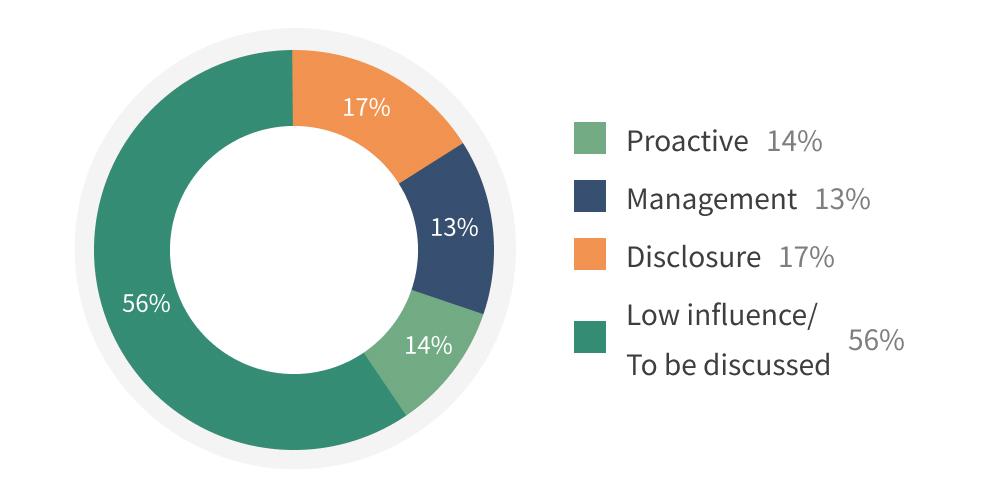

Results of the Preliminary Survey on the Supply Chain's Climate Response Status

- In 2022, we conducted a preliminary survey on the climate response status of the supply chain to serve as a reference for formulating climate change action plans in the future.

- We completed initial questionnaires for 234 key suppliers in 2022.