GREEN ECONOMY

Formulated Strategies, Achieve a Green Economy

Green Product

Starting from the product life cycle, the company continuously develops innovative capabilities such as green design and green production to reduce environmental impact and fulfill carbon reduction commitments.

Chemical Management

In compliance with regulations and international initiatives, the company aims to protect employees by implementing reduction and risk control measures from the source, process, and waste stages.

Through Life Cycle Assessment, Design High-quality Green Products

We use the life cycle assessment method assess the high-quality electronic products produced by the Primax Group at various stages, such as raw material procurement, manufacturing, transportation, product use, and waste, to reduce the impact of our products on the environment.

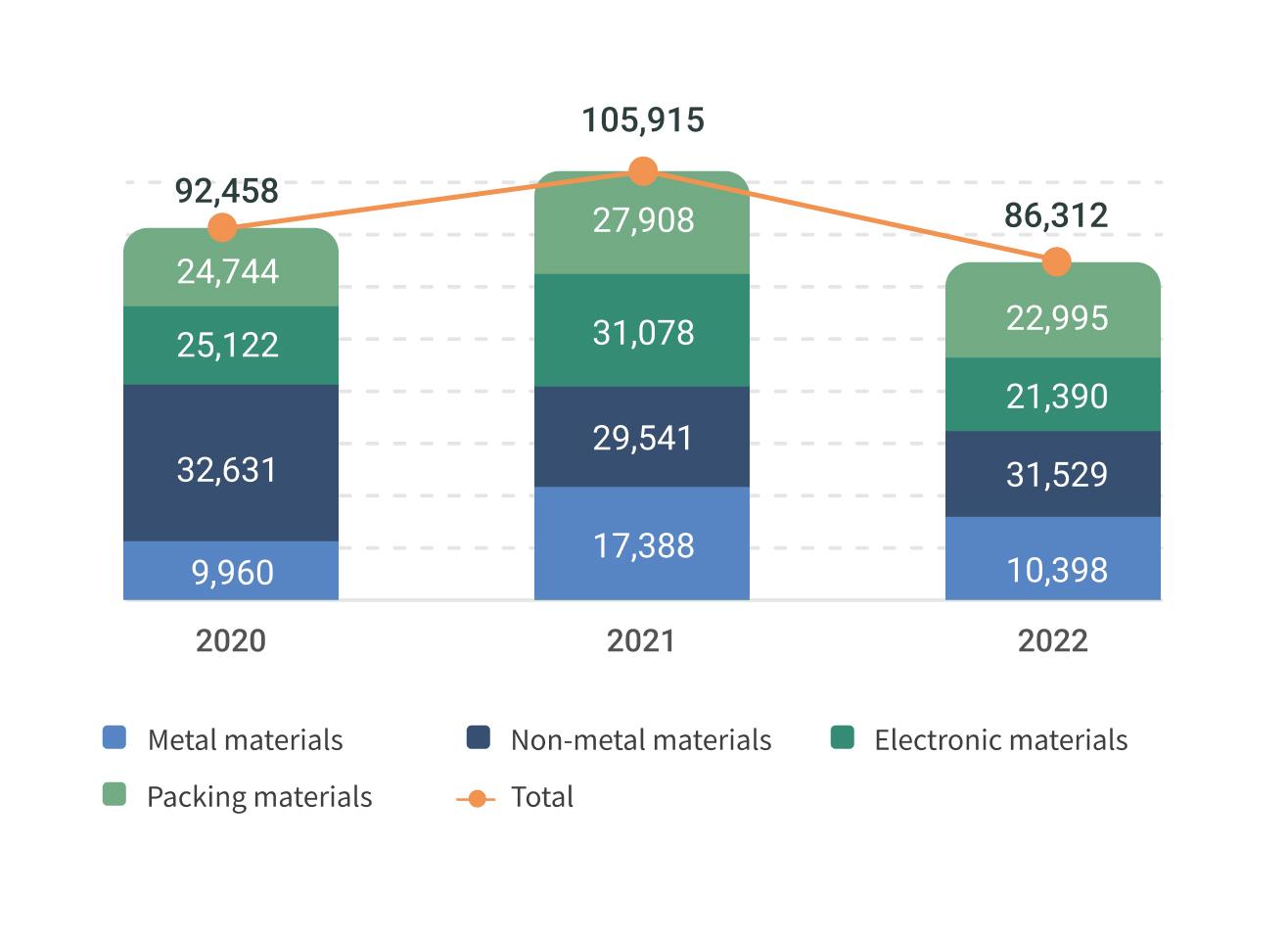

Materials

Production and Manufacturing

Waste Recycling

Green Design Achievements

- We assisted brand clients in obtaining relevant environmental protection labels (such as EPEAT) for a number of products.

- Primax Group's use of Post-consumer Resin plastics in 2022

Recycled Plastics

1,932,697

metric tons

Non-Recycled Plastics

17,805,346

metric tons

The Proportion of Recycled Plastics in All Plastic Usage

9.97

%

Green Design Achievements

- Due to improved product designs and production technology upgrade.

- Keyboard module products have reduced production hours.

Saving approximately

138,000

hrs

Green Design Achievements

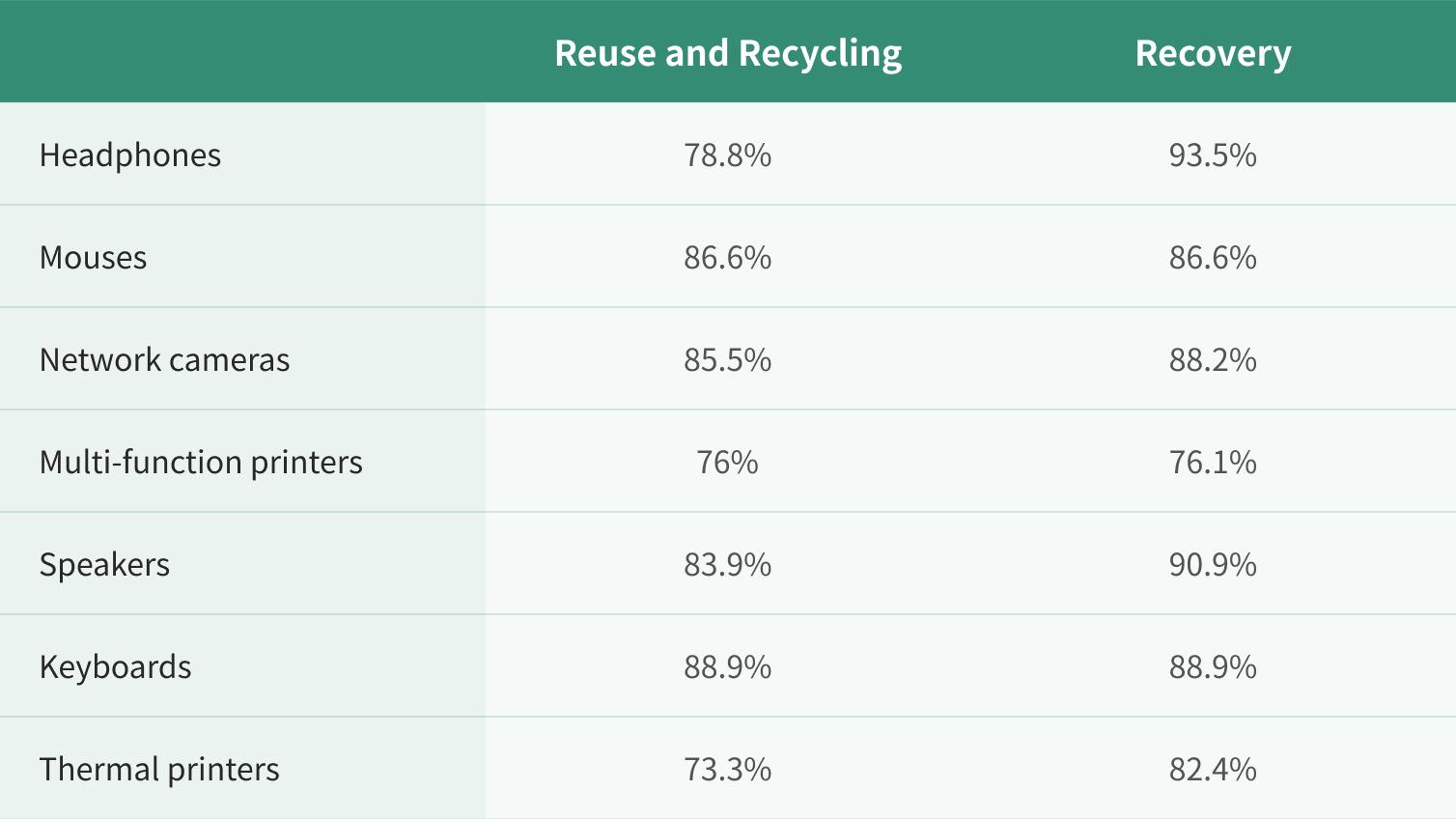

- As a mainly OEM/ODM manufacturer, Primax Group's products are ultimately disposed of and recycled by customers. Nevertheless, the Group's products still meet the requirements for WEEE recycling rates.

The WEEE disassembly analysis report for the following products is an example of how Primax Group can reduce the generation of waste from product disposal.

WEEE recycling rates: The proportion of Reuse and Recycling must be over 55%, and the proportion of Recovery must be over 75%

Build The Eco Design Management System and Environmental Footprint Database

In 2022, the Ecodesign management system and environmental footprint database were completed. Establishing a comprehensive green product management system The Primax Group has not violated any health and safety regulations or voluntary agreements related to products and services.

Ecological Design

- We establish of an Eco-design management system and an environmental footprint database combined ISO 14021, the single product regulations, and our existing information management systems in compliance with ISO 14040 and 14044, to establish a complete green product management system. During the product development process, clear requirements for ecological design are understood. By conducting life cycle assessments and integrating systematic management into the design process, products that meet low-carbon, non-toxic, and low environmental impact criteria are achieved.

Example: Low-Carbon Product Innovation Design - HVS40

- Compared to older models

Reduces Carbon Emissions

39

%

Carbon Reduction Comes from Reducing Material Consumption from the Design Source

90

%

Green Procurement

- Since 2020, Primax Group has been prioritizing the procurement of information products with large purchasing quantities and high-energy-consuming products. Our priority is to select products that carry domestic or international environmental certifications or energy-saving labels.

Procurement for Environmentally Certified Product

- 2021 procuremenfor environmentally certified products reached 62,250,000 NTD

In 2022 reached

75,350,000

NTD

Increased Compared to 2021

13,100,000

NTD

Accounting for

87.24

%

Environmental Labels & Declarations

- The products produced by Primax are mainly OEM and ODM products, and we will assist clients to apply for type 1 eco labels.

EPEAT

Multifunctional office machines, scanners

Taiwan's Green Mark

Mouses

China's Ten-Ring verification

Scanners

EU CE, China CCC

Electrical safety verification

Energy Star

Power supplies for audio products

Carbon Footprint Inspection

- Primax Group conducts carbon footprint inspection as per ISO 14067:2018 for our main products, such as mousses, keyboards, Bluetooth earbuds, speakers, and multifunctional office machines, and increases the quantity of recycled PCR and paper year by year.

The Management of Environmental Labels & Declarations

- Through the process of obtaining the carbon/carbon reduction labels for Taiwan EPA, we have successfully established a management model for product eco labels and declarations within the plants and in the supply chain. By incorporating green designs into our products, we aim to fulfill Primax's vision toward environmental protection and sustainability.

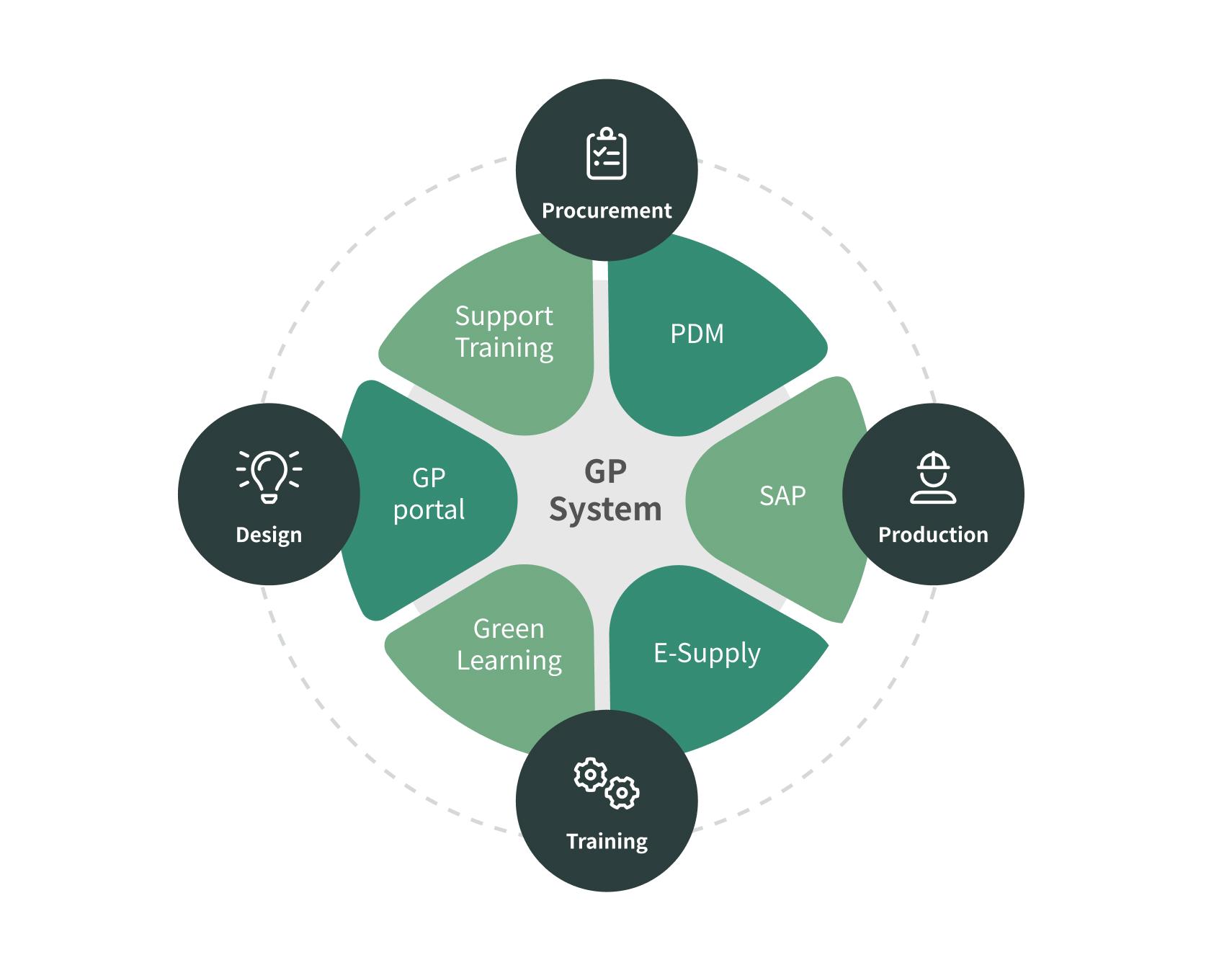

Chemical and Hazardous Substance Management

Primax has a green product management platform in place to control its raw material supply chain at the source. With PDM® system at the base, the Company has developed an integrated management information system by combining GP Portal®, SAP® and other information platforms to effectively reduce the time and cost of our processes. This integrated system controls virtually every aspect of our operation from customers' requirements, regulations, design, suppliers, procurement, production, to training.

It is mandatory for suppliers to guarantee that all products sold to the Group are free of hazardous substances prohibited by local regulations, whether in raw materials, dyes, solvents, consumables, packaging, or production process. Furthermore, suppliers are also demanded to comply with Primax's specific requirements and terms of QW- 5 Q 002 - Green Product Chemicals Specification for all substances contained in raw materials, dyes, solvents, consumables, packaging, and production process.

Compliance with Law

- The sources of raw materials produced and used by Primax Group are in compliance with the EU Restriction of Hazardous Substances Directive (RoHS), the EU Registration, Evaluation, and Authorization of Chemicals (REACH), California Proposition 65 (Prop 65 ), and the US Toxic Substances Control Act (TSCA). We will respond to changes and updates of laws and regulations one year earlier.

Hazardous Substance Disclosure

- In 2022, we incorporated all regulated substances specified in IEC 62474 into the GP Portal database, allowing us to clearly determine whether materials provided by suppliers contain regulated substances as specified by IEC 62474. In addition to meeting the content of IEC 62474, this enables us to trace the chemical substance usage of upstream suppliers. Information disclosed to customers includes products passing 100% of health and safety assessments, compliance declarations, hazardous substance test reports, material safety data sheets, and compliance reports for safety/EMC. In 2022, there were no incidents violating health and safety regulations or voluntary agreements related to products and services, nor were there any associated records of fines or penalties.

Hazardous Substance Management and Execution

- Primax Group adheres to the requirements of the IECQ HSPM QC080000 established by the International Electrotechnical Commission. We obtain third-party verification certificates and implement hazardous substance management accordingly. This includes regulatory and customer requirements, part approval, supplier management, incoming inspection, production, inventory, finished product shipment, and relevant training. Each production site of the group is equipped with chemical laboratories equivalent to third-party testing institutions, enabling analysis and management of important hazardous substance contents. Instruments are regularly calibrated and tested against third-party institutions, and personnel must undergo appropriate training and testing before conducting inspections. In late 2020, Primax introduced an incoming inspection information platform to digitize incoming inspection management (Barcode labeling and reading), ensuring the accuracy of each test data and sample information. Upon identifying toxic substances in products, immediate measures are taken to reduce or eliminate these substances, including selecting new suppliers and developing safer sources of new materials. These efforts eliminate toxic substances from the process, protecting both workers and consumers using Primax technology products, as well as preserving environment from pollution.

Reduction Project

- The EU, the US, and Japan have all prioritized the regulation of such compounds and enacted relevant regulations, our group has completed a control plan for phthalates. China strengthened its VOC control program in 2020, focusing on paints, inks, adhesives, and cleaners containing VOCs. After a thorough factory inspection, we have replaced non-compliant products, and the paints, inks, adhesives, and cleaners currently used meet the requirements. Furthermore, we are controlling substances such as 1-bromopropane, benzene, toluene, methanol, dichloromethane, hexane, trichloroethylene, tetrachloroethylene, and N-methylpyrrolidone. We are investigating whether the raw materials, consumables, and chemicals used in the factory contain these substances, setting reduction plans, and aiming to prohibit their use by the end of 2023. From Q4 2021 to the end of 2022, we have investigated a total of 71,238 items (including consumables), with 93 containing any of the above substances. While there are currently no alternative materials due to product characteristics, their use complies with local occupational exposure limits.

Management Flowchart

STUDY

Primax studies new environmental regulations thoroughly and makes preparations before the new rules are effected.

SHARE

Suppliers generally lack the resources to keep up with new rules. Once Primax finishes studying new regulations, the Company shares its findings with suppliers through GP Portal®, thereby helping them understand the requirements of new laws and guide them towards GP.

TRAINING

In addition to sharing knowledge, we also organize training sessions and invite suppliers to participate.

SURVEY

Through GP Portal®, we investigate the state of materials used in all our parts and gather test reports relating to them.

REVIEW

The data returned by suppliers will undergo a professional review by our Green Team. A systematic alert has been implemented in GP Portal® to warn the reviewer of hazardous substances or responsible minerals, which improves the accuracy and completeness of the review process.

SAMPLING

Once review is completed, the E-Supply system will notify inspectors which parts to undergo the XRF test based on the sampling plan, whenever a batch of purchased materials are due.

XRF

Primax has XRF instrument in place. The Company performs raw material tests everyday, and all test results are uploaded onto the PLM system. Any problem identified from the tests would trigger a series of corrective actions.

MANUFACTURE

Apart from input materials, Primax also exercises control over all consumables used in production, such as alcohol, cotton, solvents etc. All of which are controlled using the GP system. Green/HF production lines also undergo the same identification and clearance process.

ANALYSIS

XRF is performed not only to test input materials, but also to retest finished goods to determine whether they are contaminated during production, and thereby ensure compliance with GP.

SHIPPING

We pack and ship only the products that pass all tests.